Annual Journal 50 – 2016

Abstracts:

- Ductile cast iron creates value

- The story of drinking water systems through the centuries

- Quality assurance through modernisation and increased flexibility

- The Lusatian metropolis of Cottbus puts its trust in ductile cast iron valves and fittings

- Numerical simulation & rapid prototyping in the foundry at JMA Hodonín, a VAG-Armaturen GmbH company

- A milestone in water supply

- Time saving and flexibility in the installation of hydrants thanks to a new modular system

- DN 1200 butterfly valves for Fernwasserversorgung Elbaue-Ostharz GmbH – valve replacement in the raw water tunnel at Wienrode waterworks

- Simple and more reliable house connection system without parts that will get lost

- The steady renewal of the “Auer Ring” long-distance drinking water system in the Western Ore Mountains in Saxony – an interim report

- Kanzingbach power station (Tyrol) with a high boost in output – increased security provided by “leak-before-break” fracture mechanics design of turbine pipes

- Trenchless through the Badrina biotope – enthusiastic visitors follow the pipe pulling-in process at the site open day

- Torrent bed-load barrier on the Schnanner Bach

- Guaranteed snow for the ski jumping hill in Planica

- District heating pipeline with water from Lake Geneva in La Tour-de-Peilz (CH)

- The planning of pre-insulated cast iron pipelines

Themes, Authors, Abstracts, Keywords (Details)

Ductile cast iron creates value

By Ulrich Päßler

For quite some time now it has been clear to see that price alone is not the only decision-making criterion when it comes to durable capital assets because it takes no account of the aspect of a sustainable investment strategy. This applies to supply infrastructures in particular because the proportion of material costs to overall costs is usually under 10 %. This article summarises the innovative properties of ductile cast iron as a material in terms of its effect on the various life phases of supply and sewage disposal pipelines. These include its sustainability throughout the entire life cycle and especially the ability of pipelines to operate for decades without problem and without detriment to the drinking water quality as well as the pioneering role of ductile iron pipe systems in the establishment of the trenchless installation techniques, which also makes an important contribution to environmental protection in towns and cities. And not least it also includes the use of resources in the production of ductile iron pipe systems which, without exception, are made of recycled scrap steel and iron. Ductile iron pipe systems offer a secure route to true sustainability.

Key words: Sustainability, water management, material, ductile cast iron, value, metallic material, pipes, fittings, valves, production, centrifugal casting machine, energy, demands, raw materials, resources, ecological and economic sustainability, budget, commercial businesses, public sector, protection of health, supply, essential for life, drinking water, sustainability assessment, sustainable superiority, innovative properties, phases, supply and disposal projects, product properties, 15th century, gardens of the Palace of Versailles, Wilhelmshöhe mountain park, town of Kassel, World Heritage site, cast iron piping, fountains, UNESCO World Heritage, Octagon, Hercules statue, Harald Roscher, Hessen Kassel museum landscape, grey cast iron, longevity, factor of sustainability, ductility, material property, cast iron pipe systems, deform flexibly, pressure of water, external loads, stability, application conditions, linings, coatings, development, joint systems, installation, operation, maintenance, overhauling, economic advantages, trenchless laying techniques, life span, restrained positive-locking push-in joints, BLS®/VRS®-T, thrust blocks, changes in direction, compared, efficiency advantages, cost savings, excavation work, cover depths, trench widths, sand beds, polyurethane, cement mortar, pipe trench, material and transport costs, excavation material, roughness, slight pressure losses, pump configurations, damage rates, calculations, provisions, repairs, maintenance, pipe location finding, cost comparison, initial investments, additional financial outlay, investments, technical planning, laying, sea outfall pipe, district of Binz auf Rügen, European Association for Ductile Iron Pipe Systems/Fachgemeinschaft Guss-Rohrsysteme e. V., EADIPS®/FGR®, consultancy skills, engineering skills, planning support, steel scrap, production, health-related properties, drinking water legislation, plastics, impermeable, fluorinated and chlorinated hydrocarbons, method of operating, snow-making equipment, ski jumping hill, Slovenia, district of Planica, directional drilling project, River Havel, city of Berlin, ductile iron pipes, DN 700, assembling, traction head, single pipe process, raw materials, recycled material, iron scrap, recyclable, consideration of value, material features, drinking water supply, waste water disposal, high-performance applications, fire-extinguishing systems, energy industry, hydropower stations, soil conditions, height differences, pressure differences, trenchless laying technique, sustainability aspects, jointing technologies, high tractive forces, burst-lining, press-pull, horizontal directional drilling (HDD) techniques, trenchless installation processes, open trench methods, cost savings, CO2 emissions, noise, traffic obstruction, network management, water supply networks, renewal rate, service life, remaining service life, investment pattern, value destruction, depletion of assets, supply obligations, materials, longevity, investment strategy, investment cycles, network, DN 400, epoxy bonding layer, zinc coating, exposed for checking, no corrosion attack

The story of drinking water systems through the centuries

By Jürgen Rammelsberg

The “50th” anniversary issue of the EADIPS®/FGR® annual journal has been an occasion to look back over the history of 500 years of drinking water transport and distribution. This area of life is inseparably linked to the traditional material of “cast iron”: it has put its stamp on the development of drinking water supply for half a millennium but, with a constant influx of improvements, optimisations and innovations over this timespan, it has nevertheless remained ever young. The cast iron pipe industry, in collaboration with its users, has always managed to keep abreast of the latest state of the art with a modern and sustainable piping system comprising pipes, fittings and valves.

Key words: Historical view, story, drinking water systems, through the centuries, development, civilised society, technical expertise, setting of standards, supply of drinking water, Ancient Rome, Frontinus, Water Commissioner for Rome, transport pipelines, aqueducts, water, sources, gravity, cities, technical infrastructure, legal and financial principles, technical standards, management, royal houses, Baroque, fountains, palace gardens, pressure pipelines, water pipeline, cast iron pipes, city of Augsburg (Germany), Dillenburg Castle, cast-iron flanged pipes, Versailles (France), artificial cascades, Kassel-Wilhelmshöhe, UNESCO World Heritage site, cast-iron pipeline, pumping house, River Havel, Ruinenberg, fountains, Sanssouci, production, casting carousels, Industrial Revolution, cast iron pipe systems, generate energy, steam engines, progress, hygiene, population, centrifugally cast pipe, de Lavaud process, individual production, sand moulding technique, production, production of cast iron pipes, centrifugal casting process, joint technology, production technique, requirements, pipes in stone, pipes in vitrified clay, pipes in lead, socket-shaped ends, putty, higher pressures, flanged joints, sockets stopped with tarred hempen rope, lead, vulcanised rubber, pipe joint, flexible, able to be bent, longitudinally adjusted, earth movement, subsidence, “union” screw-gland socket joint, water, gas, packed sockets, assembly of joints, restrained push-in joints, TYTON® and Standard gasket, tightness, pushing, spigot end, bursting pressure of the pipe, flexibility, useful life, trenchless installation techniques, material developments, Iron Age, grey cast iron, lamellar graphite cast iron, smelting, iron ore, furnaces, recycled, scrap, steel scrap, cast iron scrap, old cars, cupola furnaces, mechanical properties, type of structure, form of graphite, ductility, longitudinal bending strength, elementary carbon, graphite nodules, plasticity, deformability, pipes, fittings, accessories, EN 545, ductile cast iron, fittings, valve bodies, spheroidal graphite cast iron, EN 1563, technical standardisation committees, loading capacity of pipes, brittle grey cast iron pipe, ductile iron pipe system, pipeline construction, development, protection system, oxygen, oxides and hydroxides of iron, elementary iron, corrosion damage, perforation, brown discoloration, corrosion protection, production of iron pipes, external protection, zinc, bituminous finishing layer, tar, cement mortar lining, synthetic resin finishing, epoxy, polyurethane, porosity, soil electrolyte, insoluble zinc salts, pores, points of damage, electrical resistance, corrosion current, precipitation, zinc reaction products, pH value, acid soils, bog, marshland, peat, protection mechanism, alkaline medium, alkaline electrolytes, zinc salts, zincate, cement mortar coating, EN 15542, DN 600, zinc coating, coating thickness, resistance of the coating, hydration, inert fibres, mechanical loads, trenchless installation, open trenches, difficult soils, large-grained or rocky excavation material, inspections, aggressive soils, iron surface as good as new, tar and bitumen paints, state of the art, enamel, types of protection, barrier layers, specific coating resistance, pore-free, epoxy coating, epoxy powder, surface, body, polymerisation reactions, protective layer, minimum coating thickness, EN 14901, requirements and test methods, complete enamelling, silicate technology, craft of enamelling, cast-iron ovens, inorganic lining, DIN 51178, butterfly valve enamelled on the inside, restrained push-in joints, longitudinal forces, changes of direction or cross-section, junctions, dead ends, thrust blocks, nominal sizes, DVGW worksheet GW 310, EADIPS®/FGR® E-Book – chapter 9, friction-locking push-in joints, sharp, hardened teeth, retaining elements, Tyton SIT®, Novo SIT®, TYTON SIT PLUS®, sealing systems, positive-locking push-in joints, welded beads, force-transmitting elements, TIS-K, BLS®/VRS®-T, distribution of forces, socket and spigot end, high-pressure applications, turbine pipelines, hydroelectric power stations, snow-making equipment, mountains, chapter 22, construction technology, trenchless installation and renewal techniques, horizontal directional drilling technique, HDD technique, city of Valencia (Spain), pipe pulling technique, Berliner Wasserbetriebe, new pipes, auxiliary pipe technique, DN 80, DN 500, pipe replacement, soil, rocket plough, pipe string, route, rural areas, structures, height-adjustable plough, pipe string, soils with large, sharp-edged stones, static burst lining, same route, old pipeline, fragments, materials resistant to notching, pipe relining, cross-section, DN 800, water consumption levels, flow speeds, wall thicknesses, Preliminary Technical Conditions of Supply, minimum wall thickness S0, grey cast iron pipes, association standard, Technical Conditions of Supply, Wellinger study, assessment bases, load assumptions, DIN 28600, DIN 28610, nominal wall thicknesses, circumferential stress, pipe wall, minimum wall thicknesses, wall thickness series K 10, K classes, wall thickness classes K 9 and K 8, standard wall thickness, ISO 2531, EN 545, machine control, process optimisation, EN 14801, pressure classification, products, water and wastewater pipelines, pressure class C 40, improvements, welding process, perfect penetration, stress states, allowable operating pressure PFA, marking standard, EADIPS®/FGR®-NORM 75, annual journal, cast iron pipe industry, improvements, optimisations, innovations.

Quality assurance through modernisation and increased flexibility

By Max Altmannshofer

A foundry has to do battle in a market with constantly increasing requirements for flexibility. Production batches are becoming ever smaller while the expense of retooling increases. At the same time, energy consumption has to be reduced and environmental and occupational safety requirements are becoming stricter. In such cases only decisive action can help: the latest medium frequency induction furnaces provide the solution. Performance and flexibility increase, costs decrease and process reliability improves.

Key words: Quality assurance, modernisation, increased flexibility, TALIS Group, Frischhut foundry, Neumarkt-St. Veit, production, energy conservation, environmental protection, industrial safety, just-in-time deliveries, fittings for water supply, fittings for wastewater disposal, batch sizes, delivery times, development, demands, flexible production, high quality standards, energy, resources, renovation, furnace technology, parent company, TALIS Group, charging system, composition hall, moulding plant exhaustion, energy management, production flexibility, epoxy powder, DN 80 flanged spigot, special length, PN 16 flange, puddle flange, branch connection, 1“ internal thread, DN 80 double flanged 90°duckfoot bend, PN 40 flanges, 2“ internal thread, 5 tonne medium frequency furnace, renovation measures, Otto Junker furnace manufacturer, district of Simmerath (North Rhine-Westphalia), mains frequency furnaces, range of parts, magnetic bath movement, production flexibility, process reliability, maintenance friendly, mains frequency smelting shop, maintenance costs, sump, heating up, iron, sustainable production.

The Lusatian metropolis of Cottbus puts its trust in ductile cast iron valves and fittings

By René Pehlke

Ensuring the security of the drinking water supply is the most important task of a water supplier. He can fulfil this task more easily and reliably if he places his trust in the competence of his supplier and not simply on the “cheapest” offer. Valves and fittings in ductile cast iron as a complete package from a single supplier offer the assurance of the problem-free construction and sustained service of a supply network with a long working life. More and more clients are beginning to appreciate this concept

Key words: Valves, fittings, DN 400, DN 600, city of Cottbus, ductile cast iron, construction projects, “Straße der Jugend”, Lausitzer Wasser GmbH & Co. KG (LWG), ring road, Dresdener Straße, supply pipelines, DN 80, drinking water junction, main pipelines, grey cast iron pipes, hit by a bomb, steel pipes, DN 500, Cottbus-Sachsendorf waterworks, drinking water pipelines, districts, Spremberger Vorstadt, Sandow, Ströbitz, city centre, Head of the Technical Department, Marten Eger, Dr Lothar Bohm (Technical Office at LWG), new drinking water supply, drinking water mains pipelines, grey cast iron, construction stages, drinking water feed-in, Cottbus-Fehrower Weg waterworks, valves and fittings manufacturer, Keulahütte GmbH, town of Krauschwitz, fittings, PN 10, EN 545, double eccentric butterfly valves, EN 593, resilient-seated gate valves, EN 1171, fittings and valves, epoxy powder coating, RAL-GZ 662, quality association for heavy-duty corrosion protection of valves and fittings, quality assurance, production cycle, casting process, machining, coating, assembly of the valves, product quality, product characteristics, ductile cast iron, construction features, bearing, valve disk, composite bearing bushings, polytetrafluorethylene (PTFE) layer (sintered), wear, sealing set, seal, working life, construction material, EN-GJS-400-15, modern cast iron material, strength, elongation properties, dynamic loads, minimum elongation at break, tensile strength, safety strategy, unacceptable overloading, plastic deformation, breaking point, choice of corrosion protection, process and material development, type of protection, pipeline construction, valve parts, process and quality parameters, integral corrosion protection, working life expectations, body seat, breaks in the protective layer, nickel-chrome seating surface, valve seat, coating thickness, once-through principle, blasted, cleaned, heated, adhesive strength, technical diffusion resistance, pore-free coating, high impact strength, operating conditions, resistance to underrusting, points of imperfection, high resistance to chemicals, fitness for contact with drinking water, repair kits, same type of material, individual parts, package of products, gearing, electric drive, controls, valve manufacturer, drive supplier.

Numerical simulation & rapid prototyping in the foundry at JMA Hodonín, a VAG-Armaturen GmbH company

By Radim Hnilica

Previously castings were developed in a laborious sequence of individual steps before they were ready for series production. This involved pattern as well as gating and feeding system being optimised by sample castings and subsequent modifications until their quality reached an acceptable level. With simultaneous engineering these stages can overlap and be shortened in time by computer-aided construction, strength calculation using FE methods and filling and solidification simulation. The casting takes shape with its gating and feeding system on the computer before the real moulding pattern is produced. A further acceleration of the process is achieved by using 3D printers to produce the moulding pattern. While this optimisation phase used to take weeks and months, these days this can be shortened to just a few days.

Key words: Product development, valves, ductile cast iron, numerical simulation, rapid prototyping, foundry, Czech company Jihomoravská armaturka spol. s r.o. (JMA), city of Hodonin (Czech Republic), VAG-Armaturen GmbH, development time, preparation time, new products, customer requirements, simultaneous engineering, casting simulation, solidification simulation, product development, 3D construction software, strength features, finite element methods (FEM), production feasibility analysis, casting prototype, 3D data, casting sequence, solidification sequence, simulation software, design of the cast part, casting defects, prototype, solidification analysis, optimisation of castings, input parameters, validation, simulation parameters, grey cast iron, ductile cast iron, green sand process, detection of defects, standardised casting systems, filters, feeders, modelling, Autodesk Inventor, strength calculations, defects, wall thickness, imperfections, cold laps, optimisation possibilities, casting walls, functionality, strength, strength analysis, pilot-operated control valve, VAG PICO®, total weight, cost effectiveness, drawing documentation, gating technique, feeding technique, internal porosity, cast part, machining of the castings, 3D printing, optimisation, Poly-Jet technique, thin polymer layers, UV light, hardened, build tray, Z-axis, precision of printing, fastening elements, model production, model printout, shell, stiffening elements, epoxy resin, precision of the printing, cleaning, surface, pattern plate, moulding line, development process, mechanical properties, cycles, air impact moulding line, dimensional alterations, damage, rubber-based materials, seal prototypes, seals, office printer, CNC centres, core model, production of the core box, model printing, pattern shop, sand-blasted cast parts, ultrasound, ultrasound testing, inside of the cast part, micro-porosity, processing of the cast part, 3D measurements, precision of form, precision of geometry, finishing, assembly, cast part prototypes, preparation of cast parts for production.

A milestone in water supply

By René Mattern and Sebastian Ebert

Regional economic development is usually accompanied by an increase in water supply requirements. Although a more than 100 year old reservoir may well serve its primary purpose of supplying the local community, as an essential part of a more far-reaching regional water supply it needs components (pumps, valves, etc.) to the very latest standards of technology in order to operate sustainably. Valves in spheroidal graph-ite cast iron provide the best conditions for this.

Key words: Valves, DN 150, DN 300, water supply, drinking water, ground water stream, River Aare, River Reus, municipality of Windisch, district of Brugg – Swiss Canton of Aargau, estuary, construction, new Chapf reservoir, people of Windisch, service water capacity, an extinguishing water reserve, new plant, company ERHARD GmbH & Co. KG, latest technology, planning, construction, reservoir chambers, total capacity, gate valves, PN 16, nozzle check valves installed upstream, staged pumping station, TMH Hagenbucher AG, city of Zurich (CH), ERHARD valves, DN 200, gate valves, DN 300, technology, quality, quality valves, sustainable operation, selection criteria, hydraulic design, resistance-free, low ? values, efficient, booster pumps, optimum flow characteristics of body construction, resistance, back-pressure, water hammers, flow resistance coefficient (? value), ROCO wave, flow results, disk, internal protection, enamelled internally, know-how, engineering, service, after sales, sustainability, manufacturer, specialist dealers, requirements, working life, spare parts, years of use, Windisch spinning mill, pumping station, pumps, reducing costs, restored tower, valve chamber, building protection order.

Time saving and flexibility in the installation of hydrants thanks to a new modular system

By Daniel Buri and Andreas Schütz

An exemplary illustration of the increasingly complex requirements for system components for drinking water networks can be seen in what was originally a simple component – the bottom part of a hydrant. First of all, components of this kind must meet the demand for durability and functional reliability. Then, as far as possible, their height should be able to be adjusted manually, without additional tools, in the pipe trench and it should be possible to exchange the valve in both unpressurised and pressurised states. Development has resulted in a smart system construction kit

Key words: Lower sections of hydrants, modular system, time saving, flexibility, installation, hydrants, requirements, types, versions, options, customers, water suppliers, designs, range, parts, stock, development, range of modular hydrant lower sections, VARIO 2.0, height adjustable, inlet bend, polymer concrete base, vonRoll hydro (suisse) ag, components, function, design phase, automobile sector, mechanical engineering, standard, universal main valve seat, types of valve, putting on a cover, underground hydrant, riser pipe, adjustable, fixed height, bottom parts, tee-fitting, flanged branch, length, standards, guidelines, certificates, sealing systems, radially and conically sealing valves, no excavation work, overhaul work, full mains pressure, dismantled, double shut-off ball, twin-hole drainage system, height adjustment, bayonet principle, patented bayonet system, protective cover, bolts, telescopic pipe, initial position, stop, adjustment range, steps, special lengths, polymer concrete base, foundation, hydrant combination, surface hydrant, cover depth, tunnel hydrants, standard components, double shut-off, pre-assembly work, trench, components, time, costs, terrain, positioning, rubber protective cover, connection point, dirt, adjustment, connection pipelines, stop valves, house connections, paving slabs, wooden wedges, introduction onto the market, storage space, logistics, individual parts.

DN 1200 butterfly valves for Fernwasserversorgung Elbaue-Ostharz GmbH – valve replacement in the raw water tunnel at Wienrode waterworks

By Frank Schmidt und Ursula Ritter

When it comes to maximum security, longevity and hygiene for drinking water production equipment, fully-enamelled ductile cast iron components are right at the top of the operator’s wish list. Therefore when large DN 1200 butterfly valves needed to be fitted in narrow dam outlet structures, only expertly engineered constructions could be considered. Düker’s double eccentric butterfly valves with full etec enamel-ing (inside and outside) meet the requirements of a major German long-distance water supplier to perfection.

Key words: Butterfly valves, DN 1200, Fernwasserversorgung, Elbaue-Ostharz GmbH, district of Torgau, valve replacement, raw water tunnel, Wienrode waterworks (Harz), water transport network, major waterworks, location of Wienrode, location of Torgau, location of Mockritz, Saxony-Anhalt, Saxony, North-East Thuringia, drinking water, capacity, tunnel, raw water, Rappbode dam reservoir, drinking water, pipeline replacement, commissioning, inspection, valves, tunnel outlet structure, tight conditions, fittings, component parts, structure, dismantling, installing, double eccentric, fully enamelled, PN 10 butterfly valves, type 451, valve manufacturer, etec enamel, pipelines, raw water feed, flanged spigot, dismantling joint, assembly, flange, pipeline components, quality features, quality and operational reliability, type of application, robust and stable construction, Düker butterfly valves, material characteristics, enamelling, without compromise, reliability and longevity, properties, inert, diffusion-tight, impermeable to gas, tasteless, as smooth as glass both inside and out, growth of biofilm, adhesion, invisible dirt, wearing of elastomers, corrosion resistant, interface of the material, fusion layer, cast iron, disbonding, acid resistant, resistance, use in soil class III, DVGW worksheet GW 9, DIN 50929, aggressive environments.

Simple and more reliable house connection system without parts that will get lost

By Andreas Schütz

The trend towards self-explanatory installation technology with modular elements for drinking water supply is continuing: wherever possible and if necessary system components should be able to be assembled without small parts which can get lost, without tools and without written assembly instructions; they should also have integral corrosion protection suitable for all soil types for a long, low-maintenance service life. While domestic connection adapters used to be simple elements, often made by the millwright, today’s house connection systems consist of small high-tech components which meet the client’s every need.

Key words: CLICK® modular house connection system, simple, more reliable, without parts that will get lost, house connections for connecting and disconnecting water supply, requirements, integral corrosion protection, soil conditions, corrosion, working life, operation, exerting force, high operating and functional reliability, easy to assemble, installation, operating and assembly instructions, trench, special tools, tools, mud and grime, pipe trench, advantages, corrosion-protected, bayonet connection, patented anti-twist device, time-saving, range of connection devices, modular system, without tools, vonRoll CLICK®, bayonet socket, bayonet spigot end, securing elements, valve industry, double O-ring seal, components, epoxy resin, RAL – GZ 662, soils of any kind, tapping sleeve, valve tapping device, assembling, dismantling, CLICK® connection, clockwise, unlocking, axial rotation, flexibility, aligning, “PULL” marking, fitting, valve, anticlockwise, stop, difficult installation conditions, tapping bridge, tapping, mains pressure, assembly parts, water, winter months, connection concept, connection principle, connection, valve body, bonnet, connection of the bonnet, exchanging, closing body, CLICK® system, tapping tool, twisting motion, tapping process, CLICK® principle, adapters, other aids, starter range, valve testing standards, EN 1074-1, EN 1074-2, designs, isolating gate valve, auxiliary shut-off, pressureless, fitting designs, PE plug fitting, PE spigot fitting, DN 25, DN 50, dR 32, dR 63, DVGW test specification, GW 335-B4, vonRoll system of valves, drinking water supply, range of fittings, planned, vonRoll hydro, protection, functional principle, no operating or installation instructions.

‘The steady renewal of the “Auer Ring” long- distance drinking water system in the Western Ore Mountains in Saxony – an interim report

By André Clauß

Simply for geological and topographical reasons alone, the renewal of a drinking water transport pipeline in the densely wooded region of the Western Ore Mountains is no straightforward undertaking. Thanks to modern piping systems with their highly developed structural design methods, joint technologies and corrosion protection techniques, projects of this kind can be handled without problem. In the case illustrated here, the planning engineers were confronted with a fairly unusual additional challenge in the form of the soft, unbuffered water in the reservoir which, in conjunction with the cement mortar lining of the pipe, can be subject to an inadmissible increase in its pH value in stagnation phases. By using a proven method, endorsed in the DVGW regulations, of applying carbon dioxide gas under pressure in individual sections of the pipeline before acceptance and commissioning it was possible to ensure that the drinking water in the “Auer Ring” always meets the directives of drinking water legislation.

Key words: Renewal, water transport pipeline, ductile iron pipes, DN 400, long-distance drinking water system, “Auer Ring”, Western Ore Mountains, region of Westerzgebirge, interim report, choice of material, rocky terrain, geodetic height differences, choice, pipe material, pros and cons, Zweckverband Wasserwerke Westerzgebirge (ZWW), restrained push-in joints, cement mortar coating, buffering capacity of the water, stagnation, ring pipe system, in the factory, commissioning, pH value, stagnating water, South-West Saxony, rural district of Aue and Schwarzenberg, supplying drinking water, wastewater treatment, territory, rate of connection, length of the piping network, elevated storage tank capacity, drinking water supply and wastewater disposal area, supervisory areas, long-distance water pipeline system, reservoir water, Sosa reservoir dam, long-distance water system, metallic pipes, grey cast iron pipes, steel pipes, reinforced concrete pipes, DN 350, DN 800, low pressure ranges, high operating pressures, pipe bursts, concrete pipelines, DN 450, leaking sockets, summary plan, long-distance network, planning, clean water reservoir, water level, storage volume, contour, supply system=, hydraulic calculations, simulations, analysis of water requirements, pipeline, cost comparison calculation, dead pressures, pressure shock amplitudes, pipes, fittings, ductile cast iron, EN 545:2010, BLS® positive locking and restrained push-in joints, wall thickness, wall thickness class K 9, EN 545:2006, minimum wall thicknesses, pressures, C class, PFA, TYTON® push-in joints, sectional view, types of cement, DIN 197-1, application areas, DIN 2880, Annex E to EN 545, manufacturer’s specifications, safety factor, joint failure, type test pressure, hydraulic pressure, maximum allowable operating pressure of a component, PMA, pressure surge, maximum allowable test pressure of a component, PEA, safety reserves, concrete thrust blocks, bends, branches, pipeline ends, pressure testing, dismantle, components, cement mortar lining, individual sections, degree of difficulty, location, lengths, construction stages, GGG, synergies, replacing, local network pipelines, route, certain points, routes, built-up areas, logistic advantages, cross-country sections, operation, laid along the same route, old pipeline, DN 500, pipe trench, old material, trench bottom, assembly engineers, V 302 laying tool, jointing elements, ran parallel, local network pipeline, PE, sand, pipe bedding, standard coating, zinc with protective finishing layer, site logistics, intersecting roads, construction roads, sand bedding, route, shoring elements, optimise, hydraulic conditions, intermediary high points, excavated soil, assembly of joints, protective cement mortar sleeves, high and low points, venting and draining valves, all flanged tees, air valves, maintenance, shafts, eccentrically positioned DN 400/100 junction, butterfly valves, gate valves, commissioning, bypass, flushing devices, expense for supervision, DVGW-certified companies, welding beads, construction site conditions, copper gauge, pipe manufacturer, post-treatment, corrosion protection coating, valve intersection, DN 100, BLS® system, soft water, acid capacity, stagnation points, stagnation times, blast furnace cement, hydration, pore water, limit value, drinking water regulations, DVGW worksheet W 346, sample of pipe, lab, beaker, pre-carbonation, flushing, harder water, treating, on site, availability, flushing water containers, nominal sizes, pipe lengths, carbon dioxide, condition as delivered, storage, transport, installation, air, tightness, negative pressure testing process, DWA-A 139, EN 805, pressure testing, tightness testing, CO2 gas, CO2 concentration, pipeline ends, pH value rises, calcium hydroxide, Ca(OH)2, gaseous carbon dioxide, insoluble calcium carbonate, CaCO3, density of the mortar, gas pressure, connection pipeline, CO2 source, bundle of cylinders, vaporiser system, gas pressure, gas container, safety and accident prevention regulations, conditioning measures, pressure inside the pipe, consumption of CO2, pressure drop, CO2 consumption, reaction partner, surface of the cement mortar, protective coating, neutral, durability, working life, conditioning process, weather, disinfection, hydrogen peroxide, sodium hypochlorite, chlorine bleaching agent, disinfecting effect, disinfecting agent, chlorine dioxide, phosphoric acid, cost effectiveness, technical security, client, planning engineers, construction companies, pipe suppliers, working in this way, construction site panorama, old mining installations.

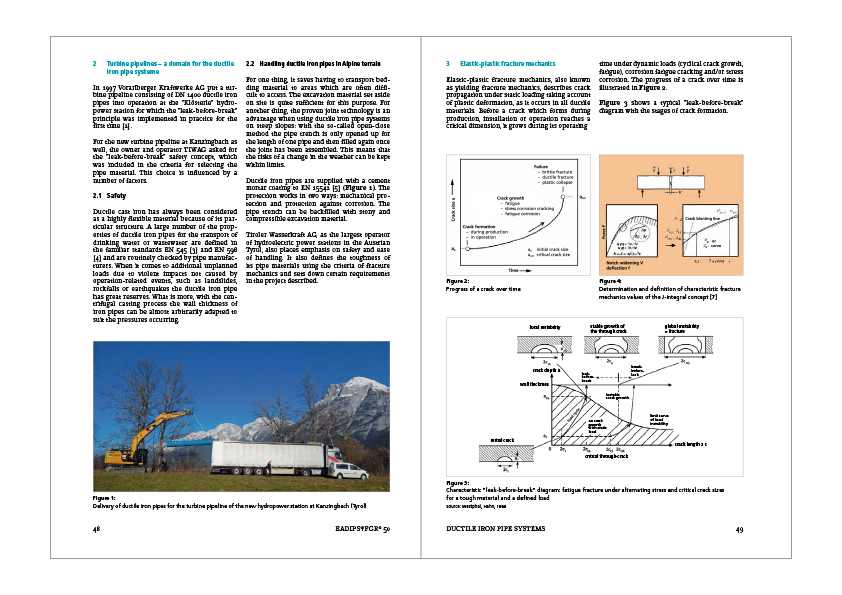

Kanzingbach power station (Tyrol) with a high boost in output – increased security provided by “leak-before-break” fracture mechanics design of turbine pipes

By Christian Auer, Andreas Hammer, Friedrich Karau, Sven Kunow, Anton Rass, Werner Rudig, Oswin Schüller

The use of ductile iron pipe systems for penstock pipelines is constantly increasing with the promotion of renewable energy sources. In this area of application the mechanical and technological requirements placed on pipe materials as well as the need for security are considerably higher than for pipes used for the distribution of drinking water. Therefore it is imperative that material modifications are developed to meet these increased demands. This report describes the safety concept (the “leak-before-break criterion), the technical material modifications and investigations necessary for practical implementation which will result in better utilisation of ductile cast iron as a material in high-pressure applications and the particular requirements for both crew and piping systems when laying turbine pipelines in alpine environments. All in all a basket of technical goodies!

Key words: Material optimisation with fracture mechanics, cast iron pipe systems, Kanzingbach power station (Tyrol), boost in output, security, “leak-before-break” design, turbine pipes, ductile iron pipes, transport, drinking water, wastewater, areas of use, penstock pipelines, hydroelectric power stations, government incentives, renewable energy, wind power, solar energy, water power, developments, Alpine region, modernising, existing plants, extension, TIWAG (Tiroler Wasserkraft AG), district of Flaurling, Tyrolean Kanzing valley, turbines, generators, control technology, efficiency, turbine pipelines, further development, reservoir, failure of a pipe, water tower, energy stored, steep slope, pressure pipelines, safety considerations, early recognition, pipe damage, high pressure applications, risk, crack appears, through-wall crack, bursting, “leak-before-break” behaviour, leaks, defect, repairing, replacing, leakage warning equipment, high-Alpine topography, planning stage, unstable crack development, standard specifications, design bases, elongation at fracture, impact energy used, American standards, ANSI/AWWA C 151-09/A21.51-09, load, pressure pipe, crack growth, force impact, notched bar impact test, turbine pipeline, Vorarlberger Kraftwerke AG, “Klösterle” hydropower station, DN 1400, safety concept, selecting pipe material, material, ductile cast iron, structure, properties, EN 545, EN 598, pipe manufacturers, unplanned loads, violent impacts, landslides, rockfalls, earthquakes, wall thickness, centrifugal casting process, pressures, working, Alpine terrain, transport, bedding material, areas difficult to access, excavation material, joint technology, open-close method, pipe trench, joint assembled, change in the weather, cement mortar coating, EN 15542, protection, corrosion, stony and compressible excavation material, Austrian Tyrol, requirements, toughness, criteria of fracture mechanics elastic-plastic fracture mechanics, yielding fracture mechanics, crack propagation, static loading, plastic deformation, production, installation, critical dimension, operating time, dynamic loads, cyclical crack growth, fatigue, corrosion fatigue cracking, stress corrosion, progress of a crack over time, “leak-before-break” diagram, J-integral concept, crack formation, progress of a crack, failure, brittle fracture, ductile fracture, plastic collapse, notch widening, deflection, crack blunting pipeline, local instability, stable growth, through-crack, global instability, fracture, crack depth, “break-before-leak”, limit curve, initial crack, critical through-crack length, fatigue fracture, alternating stress, critical crack sizes, tough material, crack resistance curves, fracture toughness, crack tip, crack propagation, crack resistance measurement, diagram, test procedure, bending load, 4-point bend, tensile and bending load, CT specimen, CT = compact tension, specimen, notched bar impact test, V-shaped notch, crack, 4-point bending test, widening of the notch, deflection, widening the crack, physical work, J0.2 value, through-crack, wall thickness, crack length not detectable, application cases, low pressure range, high pressure range, required fracture toughness J0,2, fracture toughness value, crack resistance energies, test centre for material and mechanical engineering in Innsbruck (V.A.M.), pipes, fittings, test specimens, resonance test system, 3-point bending test specimen, partial unloading process, compliance method, ISO 12135, research and development work, TIROLER ROHRE GmbH – TRM, Duktus Rohrsysteme Wetzlar GmbH, modification, types of pig iron and scrap, ferritic structure, extremely fracture-tough properties, GJS 450-10, EN 1563, modified material, mechanical and technological properties, room temperature, impact bending energy, temperature range, measurement results, elongation at fracture, tensile strength, technical yield strength, impact energy consumed, measurement parameters, sustained loading, metallurgical and production technology development work, material properties, breaking elongation values, DN 600, upper area of the route, pipeline, pathways, restrained push-in joints, PFA = 25 bar, BLS®/VRS®-T, concrete thrust blocks, pipe bends, fracture mechanics tests, anchors, thrust blocks, TYTON® push-in joints, construction time, power, summer pasturing, cable route, rocky subsoil, pipe trench, rock, stability, excavator with cutter head, material cut out, installation of the pipes, intake structure, Y-pipe, parallel installation, DN 200, excavators, installation work, timeframe, cutting work, synergy effect, elevated tank, drinking water source, Flaurlinger Alm, drinking water power plant, durability, robustness, environmentally compatible implementation, powerhouse, wetland, ecological viewpoints, amphibians, animal and plant species, habitat, implementation of the project, protected areas, old plant, specifications for aquatic ecosystems, residual water output, residual flow stretch, low water times, regulation, inflow of water, schedule, check dam structure, water catchment, construction companies, commissioning, construction time, use, power supply, water resources.

Trenchless through the Badrina biotope – enthusiastic visitors follow the pipe pulling-in process at the site open day

By Uwe Hoffmann and Stephan Hofmann

A dilapidated steel pipeline frequently in need of repair was located in an ecologically sensitive area which has meanwhile been reclassified as an FFH site. In order to avoid further disruptions due to repair work, the old pipeline needed to be replaced without disturbing the biotope and without going in with heavy equipment. Nowadays tasks of this kind are solved very elegantly with ductile iron pipes which are pulled in by means of the single pipe assembly HDD “nonimpact” process.

Key words: Horizontal directional drilling, DN 500, trenchless, Badrina biotope, visitors, site open day, pipe pulling-in, Delitzsch-Rackwitzer water supply association (DERAWA), investments, raw water supply, community of Delitzsch, Saxony, old pipeline, feature, oligotrophic standing water, low in nutrients and humus, mesotrophic standing water, medium level of nutrients, calcareous standing water, bodies of clear water, habitat type, natural environment, ponds, low in nutrients, stonewort, state of preservation, access, anthropogenic interference, fishing or angling waters, land, heavy machines, “Natura 2000” network, protected areas, European Union, EEC Directive 92/43, fauna/flora habitat directive, FFH directive, native plants and animal species, network of protected areas, EEC Directive 79/409, wild birds directive, initial situation, Delitzsch water supply association, raw water, Prellheide North and South well catchment areas, Spröda district, transport pipeline, steel, community of Badrina, district of Delitzsch, district of Scholitz, biotopes, wetland meadows, reed-beds, repair work, steel pipeline, corrosion damage, susceptibility to faults and failures, replacement, section of pipeline, Badrina biotope, pipeline, service area, inhabitants, industrial concerns, business concerns, commercial concerns, agricultural concerns, public institutions, drinking water, planning, nature reserves, construction plans, planners, trenchless installation, HDD technique, ductile iron pipes, BLS® restrained push-in joints, cement mortar coating, EN 15542, local circumstances, environmentally friendly, DVGW worksheet GW 321, gyrocompass control, navigation software, ring laser gyroscope, drill, starting pit, target pit, reference line, special version, ban on entering, directional drilling technique, magnetic tracking systems, route, computer monitor, Badrina soil, tip of the drill head, high pressure, bentonite suspension, mixture, clay, water, suspension, drill hole, recycled, restricted space, single pipe technique, assembly ramp, time for assembly, shrink-on sleeves, familiarisation period, assembly times, single-pipe assembly, resistant joint protection, directional drilling suspension, groundwater, reconnection, new pipeline, time window, construction work, directional drilling, Beermann Bohrtechnik GmbH company, town of Zeitz, drilling equipment, traction force, drilling, obstacles, workers, drilling company, heavy-duty equipment, pipe string, construction company Josef Pfaffinger Leipzig Baugesellschaft mbH, entry angle, excavation pit, sheet steel cone, excavator, locked, orientation phase, traction head, tensile force gauge, pulling in, ductile cast iron fittings, PN 10, site open day, pipe manufacturer, project, interested parties, clients, tour, uncomplicated, fast, perfect, trenchless installation, flexible, trenchless installation technique, HDD single pipe assembly, external pipe protection, length of pipeline, maximum tensile force, drilling machine, permissible tensile force, maximum tensile force measured, requirements, robustness, security, internal pressures, external load capacity, operational reliability, working life.

Torrent bed-load barrier on the Schnanner Bach

By Werner Siegele and Christoph Aigner

Ductile iron pipes are the number one choice for hydraulic engineering projects in the Alps, especially when it comes to flood protection. In order to protect a town from flooding after a mudslide a robust arch dam has been constructed which has adjustable openings through which running water containing bed load is accelerated in such a way that boulders and other river debris deposited are washed away, thus preventing conditions which lead to flooding. The adjustable openings, in a so-called inflatable weir system, are filled and activated with water from an elevated tank via ductile cast iron piping systems laid above ground. This calls for a robust piping material which is resistant to impact by rocks and to UV radiation: ductile cast iron!

Key words: Torrent bed-load barrier, Schnanner Bach, arch dam, openings, inflatable weir system, “Rosanna” stream, Verwall mountains, Tyrol, Vorarlberg border, River Inn, tributaries, town of Schnann am Arlberg (Tyrol), flooding, mudslide, bed-load material, deadwood, opening, outflow area, transport of bed-load, drag forces, flow of water, torrent and avalanche containment department, Austrian Ministry for Agriculture and Forestry, prototype, requirements, project manager Michael Posch, district of Pettneu, area of the barrier, backing up, accretion, receiving waters, cost effectively, possible solutions, civil engineers Matthias Luxner and Engelhart Gstrein, district capital of Imst, holding back, flap, gate, devices, experiences, membrane, friction, University of Innsbruck, flow model, summary of the system, flow of water, tubes, water tank, difficult conditions of terrain, reinforced concrete, valves, high-level tank, water pressure, pump, pumping house, control and switchgear station, ductile iron pipelines, system diagram, piping system, barrier wall, UV-resistant material, access, site, ductile cast iron, robustness, VRS®-T push-in joint system, rockfalls, mechanical resistance, secure operation, project data, safety requirements, special adaptors, assembly team, know-how, pre-assembly, model, wood, site, client, construction company, developer, planning, total construction time, main pipelines, jointing elements, coating, PUR-Longlife, lining, cement mortar lining, requirements, impacts, operation, flows out, bed-load stretch, video-monitored, build-ups, height difference, inlet pressure, tilt sensor, pressure of the bed-load, surge, dredging and transport work, erosion, emptied, water, cellar, volume, tablet PC, improvements, failure, emergency generator, equipping, ecology of the stream, able to pass, flow water, normal flow-off.

Guaranteed snow for the ski jumping hill in Planica

By Romana Bohm

Planica in Slovenia and Vikersund in Norway are competing fiercely with each other to achieve the greatest flight distance with their ski jumping hills. For World Cup and Championship ski jumping events of this kind, guaranteed snow is an absolute must. And this is where ductile iron pipes come into play for the operation of the snow cannons: the pipes need to be robust, they must be simple and secure to install and they have to withstand very high pressures. Installed above ground, they must be equipped with restrained joints which are easy to assemble. Ductile iron pipe systems have always demonstrated their technical and economic advantages in this field.

Key words: Snow-making system, DN 80, DN 100, DN 125, winter sports resort, production of technical snow, supply of water, snow-making system, guaranteed snow, ski-jumping hill in Planica (SLO), Planica – village of Ratece, country of Land Slovenia (SLO), winter sports centre of Kranjska Gora, “Letalnica Bratov Gorišek” ski-jumping hill, reconstruction, country of Norway (N), town of Vikersund (N), planning for the reconstruction, architect Janez Gorišek, Olympic Games in 1956, Oberstdorf (D), choice of material, company TIROLER ROHRE GmbH – TRM, piping systems, pressures of up to 100 bar, VRS®-T restrained push-in joint, tightness, loads, technical advantages, ductile iron pipes, ductile fittings, working life, water pipeline, 40 bar, KLIMA PTUJ construction company, steepness of the slope of the ski-jump, height difference, auxiliary hoist, installation, steep slope, capacity to be deflected, joint, terrain, pipeline above ground, Tyrol (A), UV-resistant, external protection, ductile iron pipeline, 90° bends, run-out area of the ski-jumping hill, starting position of the ski jump, ski-flying world records.

District heating pipeline with water from Lake Geneva in La Tour-de-Peilz (CH)

By Vincent Voyame and Andreas Schütz

Lake Geneva offers heating energy for its local communities. By means of heat pumps it can be put to good use. The pipelines installed for transporting the water from the lake consist of ductile iron pipe systems which are perfect for the job: they are corrosion-protected inside and out and their large hydraulic cross-section means that operational costs are kept low. Electrically insulating thrust resistance systems prevent the risk of damage due to stray currents and they are easy and safe to install. In short, the ductile iron pipe system meets all the conditions for transporting low-temperature district heating.

Key words: Energy efficient, transport of lake water, heat generation, district heating pipeline, La Tour-de-Peilz, Lake Geneva (CH), sustainable energy supply, reduction, CO2 emissions, using heat or cold, Switzerland (CH), heating, fossil energy sources, Lake Constance, Lake Zurich, Lake Lucerne, Lake Geneva, use, heating potential, edge of the Alps, plants, Zürich, Lausanne, St. Moritz, volumes of heat, heat pumps, efficiency levels, useful heat, energy for driving, electrical power, combustion engines, district heating network, CAD LA TOUR-DE-PEILZ, in the end, requirements, heating, hot water, technology, district heating system, pumping stations, network of pipelines, bank of the lake, heat exchanger, distance from the lake bank, depth, temperature, pumping circuit, distribution network, buildings, compression, expansion, high-performance heat pumps, domestic hot water, potential, throughput consumption, households, renewable energies, CO2, investment, district heating plants, Europe, length of the network, volume of water from the lake, connected output, energy produced, equivalent energy in terms of fuel oil, CO2 reduction, vonRoll cast iron pipes, operational reliability, cost-effective operation, working life, criteria of choice, piping system, DUCPUR, thrust resistance system, HYDROTIGHT, polyurethane, EN 545, EN 15655, surface roughness factor, hydraulically smooth, pressure losses, hydraulic cross-section, PUR coating, pumping operation, energy-related efficiency, operating costs, nominal sizes, DN 200, DN 700, closed-circuit system, double pipelines, forward and return flow, inlets, outlets, building connections, shut-off valves, main pipelines, epoxy powder, shut-off butterfly valves or gate valves for isolating sections, DN 400, shaft, external thrust resistance Fig. 2806, ductile iron pipes, helicopter, route of the pipeline, space available, water extraction point, bank of the lake, railway line, micro-tunnelling process, castors, tunnel, open installation technique, trench width, installation unit, access, components, lateral connections with valves, stray current risk, run beneath a railway line, transport pipeline, area of influence of direct-current railways, stray currents, reverse current, drive wagons, input rectifier, rails, drop in longitudinal voltage, longitudinally conductive piping system, electrical resistance, interruption, pore-free coatings, SVGW guideline W4-3 external protection system, socket joints, technical report, Swiss corrosion protection association (SGK), potential differences, soil conditions, flow of current, corrosion damage, metal structures, longitudinal conductivity, galvanic elements, series of tests, cast iron pipe systems, PUR lining, hydraulic performance, PUR coated system.

The planning of pre-insulated cast iron pipelines

By Stephan Hobohm and Karl-Wilhelm Römer

Pre-insulated cast iron pipes can provide ideal solutions for the installation of water pipelines underneath bridges or in traffic tunnels where they are exposed to the risk of freezing. But even water pipelines underground can freeze if they have to be laid with too shallow depth of cover. This article provides a comprehensive summary of all aspects relevant to planning such as calculating the dimensions of the insulation layer, integrating any trace heating which may be necessary and the design of suspension or fixing devices. There are also some valuable advices on the storage, transport and installation of pre-insulated pipes.

Key words: Pre-insulated cast iron pipe system, planning, cast iron pipes, pre-insulated cast iron pipe, thermal insulation, frost protection system, exposed water pipelines, district heating pipelines, advantages pre-insulated pipe system, handling, cost effectiveness, socket pipes, socket fittings (double socket bends, all-socket tees), ductile cast iron, EN 545, EN 598, CFC-free polyurethane (PUR) foam, overall gross density, folded spiral-seam outer tubing, EN 1506, galvanised sheet steel, stainless steel, buried pipelines, HDPE, EN 253, external influences, push-in joints, soft polyethylene, spiral bandage, sheet metal collar, shrink-on PE bandage, subsequent insulation, heat loss, stagnation times, diameters, freezing, ambient temperature, temperature of the water, thickness of the insulating layer, initial temperature, completely filled, medium pipe, DN, insulation thickness, external temperature, stagnation times, trace heating, installing heating cables, temperature of the medium, designing, drinking water pipelines, untreated water pipelines, wastewater pipelines, extinguishing water pipelines, process water pipelines, linings, mortar, blast-furnace cement, high-alumina cement, calculations, summer months, temperature increase, location, pipelines laid above ground, across bridges, temperature drop, outside temperatures, wind, area subject to frost, earth, external diameter, outer casing, type of joint, DN 80, DN 150, TYTON®, BLS®, wall penetration, size of brackets, suspension, technical data, dimensions, weight, total weight, nominal sizes, nominal external diameter, heating, planning phase, pipe carrying the medium, pipe assembly, press-fit connectors, shrink-on sleeves, wattage, electrical protection, heating circuit length, pricing levels, thermostats, adjustment possibility, remote control possibility, monitoring possibility, tolerances, control systems, Bartec, Raychem, heating circuit, minimum temperatures, maximum temperatures, material, outer casing, folded spiral-seam sheet, PE outer casing, special solutions, steel pipe, support distance, pipe length, UV resistance, reflecting surface, level of heating, solar radiation, HDPE casings, bedding materials, grain size, DVGW worksheet W 400-2, types of casing tubes, static reasons, shallow cover depths, surfaces crossed by traffic, pipe statics, depths of earth cover, subsidence, load distributing plates, concrete jacket, DWA worksheet A 139, brackets, cross-supports, bracket diameter, bracket width, minimum bracket width, suspensions, supports, longitudinal rigidity, vents, hydrants, weight of the pipe, mechanical damage, potential differences, rubber interfaces, construction of the support, slide bearings, fixed bearings, fixed points, thermal influences, pressure surges, fixed point of the bridge, positive locking, non-restrained joints, movements, assembly, types of joint, restrained friction locking push-in joints, restrained positive locking push-in joints, flanged fittings, flanged pipes, insulated on site, connection sets, internal seams, external seams, high points, DVGW datasheet W 334, aeration possibility, ventilation possibility, valve, branch fittings, double-socket tees, threaded female outlet capable of being shut off, expansion joints, change in length, coefficient of thermal expansion, angular deflections, bends, operating conditions, out of operation, winter, medium flowing through, wall penetrations, ring seals, screws, affixing, seal, denting, heat-shrinkable end caps, front, moisture, PUR foam, insulating properties, ventilation valve, construction work, pipe bundles, chains, lifting tackle, handling hooks, spigot end, rubberised forks, square timbers, stacking the pipes, assembly equipment, pipe manufacturer’s instructions, bridge abutments, petrolatum bandages, protective tape, fleece, electrician, socket transitions, special insulating sets, insulating material, spray foam, calculating dimensions.