Rohwasserüberleitung zwischen Prims- und Steinbachtalsperre

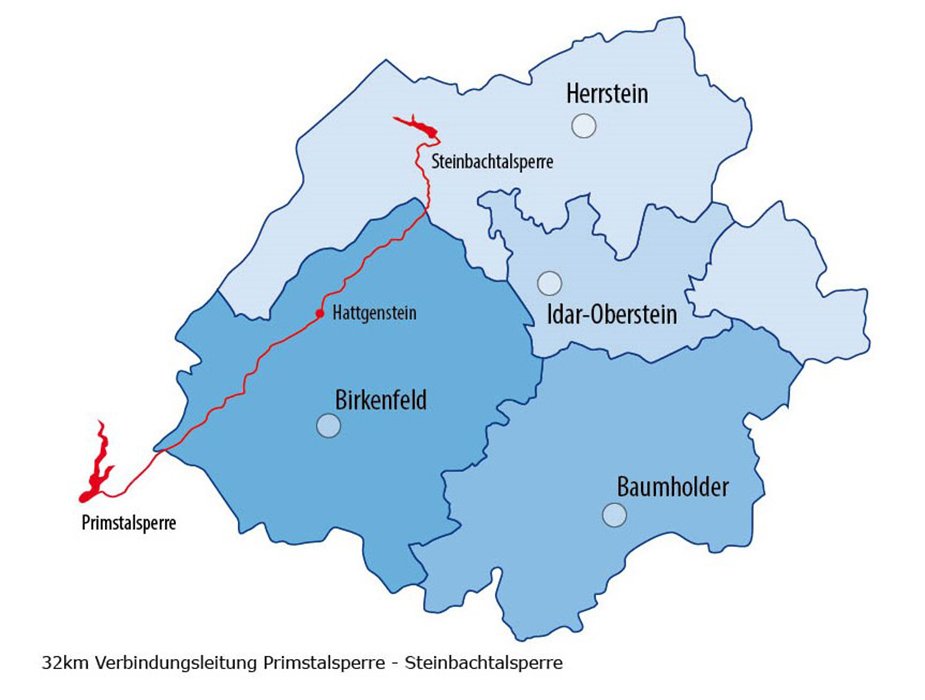

Der Wasserzweckverband im Kreis Birkenfeld hat die Aufgabe, für seine Mitglieder, die Verbandsgemeinden Baumholder, Birkenfeld, Herrstein und Idar-Oberstein, die Wassergewinnung, -aufbereitung und -verteilung für ca. 77.000 Einwohner mit einem jährlichen Gesamtvolumen von 4,8 Mio. Kubikmeter Wasser sicherzustellen.

Um auch in Zukunft die Versorgungssicherheit gewährleisten zu können, ist eine Sanierung des Staudamms der für die Rohwassergewinnung wichtigen Steinbachtalsperre erforderlich. Dies war der Grund für den Bau einer Rohwasserüberleitung aus duktilen Gussrohren zwischen der Steinbachtalsperre (Rheinland-Pfalz) und der Primstalsperre (Saarland). Während der Sanierungsarbeiten am Staudamm der Steinbachtalsperre übernimmt die Primstalsperre die Aufgabe der Wasserlieferung für das Wasserwerk Steinbachtalsperre.

Im ersten, 20 km langen Abschnitt der Überleitung wird das Rohwasser der Primstalsperre in einer Rohrleitung DN 500 aus dem Saarland bis zum höchsten geodätischen Punkt „Wasserschloss Hattgenstein“ gepumpt. Von dort aus fließt es in einer je 12 km langen Doppelfallleitung DN 400 zum Wasserwerk Steinbachtalsperre. Die dabei freiwerdende hydraulische Energie wird in einer Anlage „Pumpe als Turbine“, kurz PAT, im Wasserwerk Steinbachtalsperre zur Stromerzeugung genutzt.

Verlauf der Verbindungsleitung zwischen der Primstal- und der Steinbachtalsperre mit Darstellung des Verbandsgebiets des Wasserzweckverbands im Kreis Birkenfeld (Quelle: http://www.wzv-birkenfeld.de/aktuell2.htm)

Neben den Pumpwerken an der Primstalsperre und an der Steinbachtalsperre sind eine Vielzahl von Armaturen in Tiefpunkt-, Druckunterbrechungs- und Schieberschächten eingebaut worden.

Erhard Armaturen aus Heidenheim konnte sowohl das breite Spektrum an geforderten Armaturen abdecken als auch die dazu gehörenden technischen Berechnungen liefern. Im Rahmen des Projektes wurden Absperrklappen Typ Roco wave, Ringkolbenventile, Rückflussverhinderer, Be- und Entlüftungsventile und Kugelhähne mit entsprechenden Pass- und Ausbaustücken sowie Rohrbruchsicherungseinrichtungen mit Fallgewichtsantrieben DN 500 bis PN 40 geliefert. Beispielhaft werden im Folgenden einige der verwendeten Armaturen vorgestellt:

Die hochwertigen ERHARD ROCO wave Absperrklappen sorgen für eine zuverlässige und saubere Wasserführung. Mit ihrer optimierten Klappengeometrie zeichnet sich die Armatur durch einen geringen Druckverlustbeiwert (Zeta-Wert) aus, was zu einer Verringerung der Pumpkosten beiträgt. Das bei ERHARD entwickelte, produzierte und hier eingesetzte Schubkurbelgetriebe (SKG) ist die ideale Lösung zum sicheren Öffnen und Schließen der Klappe. Die Bewegungskinematik des SKGs ist perfekt auf den Drehmomentverlauf der Klappe abgestimmt; durch die verlangsamte Schließgeschwindigkeit wird die Druckstoßgefahr minimiert.

Rohrkeller im Wasserschloss Hattgenstein mit ERHARD Absperrklappen ROCO wave im Hintergrund mit einem hydraulischen Antrieb sowie mit verbauten Pass- und Ausbaustücken.

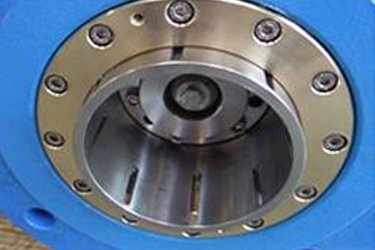

Das leichtgängige SKG-Getriebe wird auch bei den eingebauten ERHARD Kugelhähnen verwendet. Kugelhähne zeichnen sich in Offenstellung durch einen freien Durchgang und somit einem sehr kleinen Druckverlustbeiwert (Zeta-Wert) aus. Bei den in der Rohwasserleitung zu erwartenden hohen Fließgeschwindigkeiten sowie Drücken von bis zu 40 bar verringern sich durch die Wahl dieses Armaturentyps die Energiekosten für den Wassertransport.

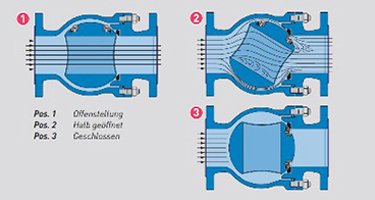

Die für die Steuerung der Wassermenge eingesetzten ERHARD-Ringkolbenventile wurden für den jeweiligen Anwendungsfall, z. B. mit Sonderschlitz-Zylindern ausgelegt. Vorteile sind:

- Optimierte Strömungsführungen ermöglichen einen kostengünstigen Betrieb.

- Die Hauptdichtung liegt in der hydraulisch unkritischen Druckzone und ist in einer Edelstahlkammer eingebettet.

Dies bietet eine optimale Abdichtung bei gleichzeitig minimalem Verschleiß. - Durch die vier breiten Führungsleisten aus -Aluminium- Bronze wird die Gewichtskraft des Kolbens gleichmäßig verteilt. Dies reduziert die Abnutzung und erhöht die Lebensdauer.

- Schon ab einen Öffnungsgrad von 4% lässt sich die Wassermenge genau steuern, was einem Regelbereich von 96% entspricht.