Briefly introduced: New generation of strainers

The ERHARD Strainer F3 10 in straight seat design is suitable for the protection of control valves, water meters, etc. It is used in water supply, water treatment, irrigation networks and pumping stations. It is offered in the nominal widths DN 50 to DN 250 and in the pressure stages PN 10, PN 16 and PN 25 (larger nominal widths and pressure stages are of course available on request).

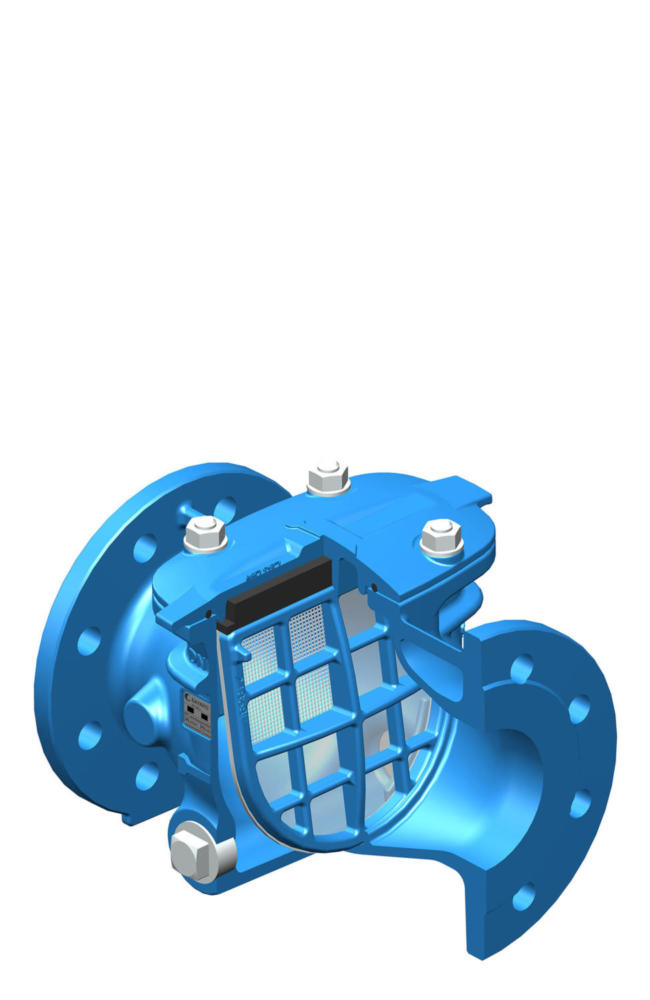

The design is compact and allows uncomplicated, easy maintenance.

Features and benefits

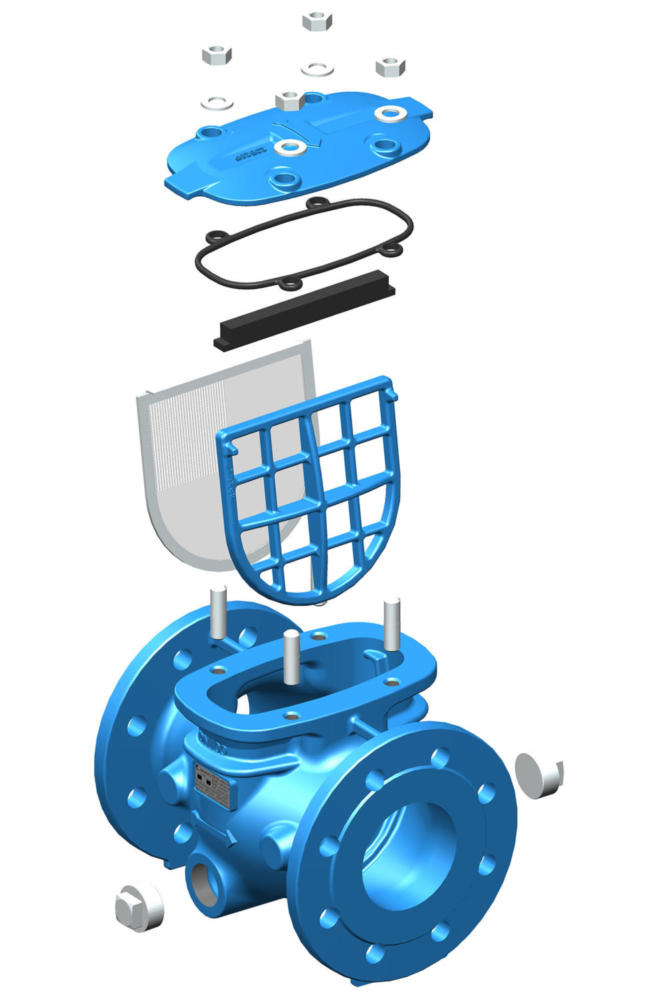

The design of the strainer is compact and allows easy maintenance thanks to the cover fixed with four screws from above. A reinforced strainer guide reliably prevents deformation during maintenance of the strainer, whose surface area is at least twice as large as the nominal size, thus minimizing pressure loss. The inclined position of the strainer minimizes the risk of clogging. The mesh size in the standard model is 2 mm. Other mesh sizes, such as 0.5 mm, 1 mm or 8 mm are available on request.

Double-sided sealing plugs made of A2 with a thread of 1 ½” allow cleaning without shutting off the line; a drain valve is optionally available. An additional flange hole on the top helps to install the valve in or out of the pipeline.

There is often little space at the bottom of the chamber; here, maintenance access from above is a major advantage.

Materials and dimensions

Materials (standard)

Housing, cover and strainer guide: ductile cast iron EN-GJS-450-10

Flat screen: stainless steel 1.4401

Seals: EPDM

Screws and sealing plugs: A2

Proven corrosion protection with powder coating

Inside and outside seamless and pore-free epoxy plastic coating (EKB), layer thickness at least 250 µm

Operating temperature

Permissible operating temperature: max. 60 °C

Author:

Matthias Müller, ERHARD GmbH & Co. KG