Jahresheft 51 – 2017

Themenübersicht:

-

Das Schwammstadt-Prinzip –

vom Rohr-Boden- zum Boden-Rohr-System – Lösungen mit duktilen Guss-Rohrsystemen -

Duktile Gussrohre im Doppelpack um die Kurve gezogen

-

Wurzelfestigkeit von duktilen Guss-Rohrverbindungen

-

Fusion Bonded Epoxy Resicoat R4® schützt erdüberdeckte Gusskomponenten seit über 25 Jahren vor Korrosion

-

Landeshauptstadt von Sachsen-Anhalt setzt auf Armaturen und Formstücke aus duktilem Gusseisen mit Epoxidharz-Pulver-Beschichtung

-

Die neue Generation eines weichdichtenden Schiebers

-

Neubau einer UV-Desinfektionsanlage im Wasserwerk Menden-Halingen der Wasserwerke Westfalen GmbH

-

Unser Antrieb für Innovation ist Optimierung

-

Elastomerdichtungen in Trinkwasseranwendungen

-

Gesamtumfahrung Biel –

Löschwasserleitungen aus duktilem Gusseisen in den Autobahntunneln Büttenberg und Längholz -

Bergbahnen Westendorf –

schneller beschneien mit duktilen Gussrohren -

Wasserkraftwerk Lago di Tomé –

Hochdruckleitung DN 400 für eine umweltfreundliche Stromproduktion -

Kleinwasserkraftwerk Costeana –

duktile Gussrohre als Problemlösung bei Erdbewegungen -

Kraftwerksleitung für das Kraftwerk Bristen im Kanton Uri

Themen, Autoren, Schnellübersicht (Detailansicht)

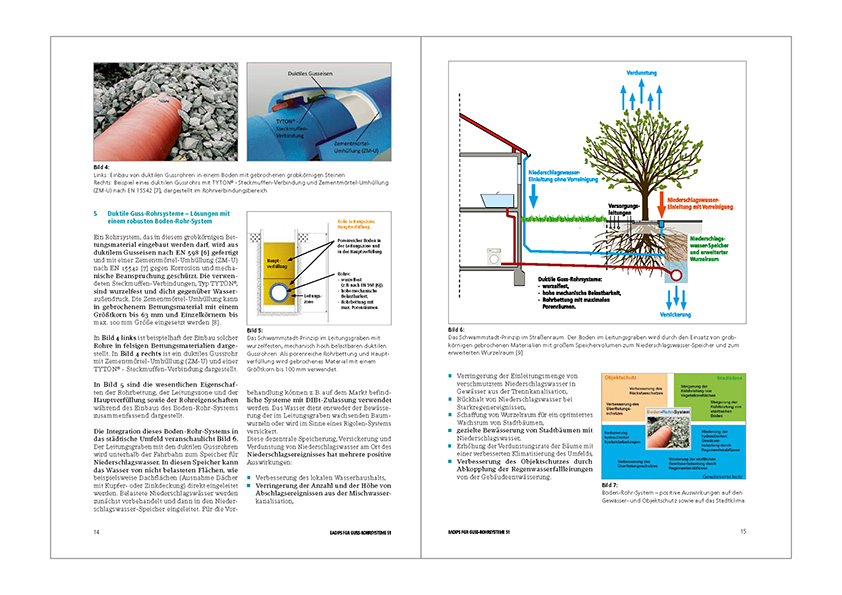

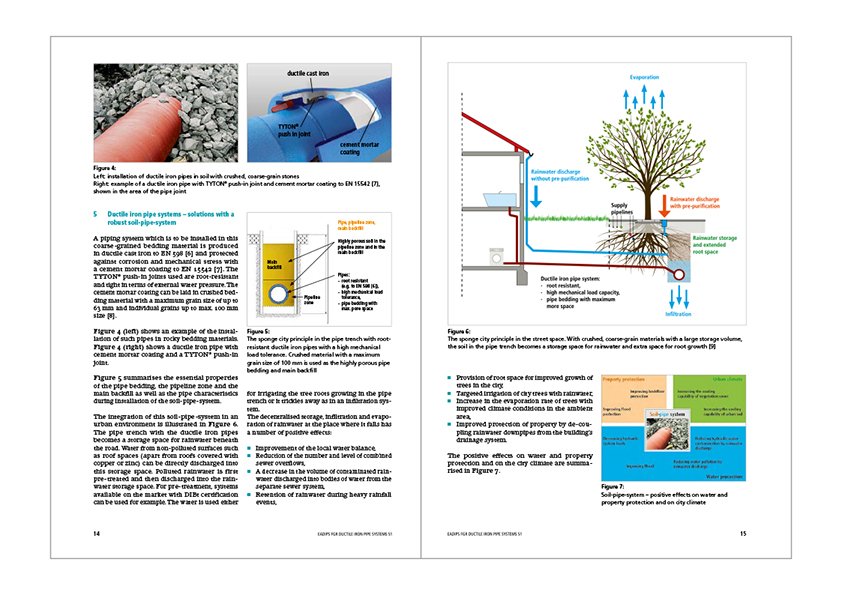

Das Schwammstadt-Prinzip – vom Rohr-Boden- zum Boden-Rohr-System –

Lösungen mit duktilen Guss-Rohrsystemen

Von Christoph Bennerscheidt

In unseren Breiten macht sich der Klimawandel mit sommerlichen Überhitzungen und Starkregenereignissen zunehmend bemerkbar, zum Teil mit Katastrophen-Charakter. Wenn es gelänge, den unterirdischen Porenraum der Bettung von Abwasserkanälen als vorübergehenden Speicherraum für Regenfluten zu nutzen und dieses Wasser auch noch den Stadtbäumen zur Verdunstung verfügbar zu machen, dann würden gleich zwei Fliegen mit einer Klappe geschlagen. Voraussetzung für diese Abwasserkanäle sind mechanisch äußerst robuste Rohre, die eine Bettung aus scharfkantigem Grobmaterial von 100 mm Korngröße verkraften und eine wurzelfeste Verbindung besitzen. Duktile Gussrohre mit Zementmörtel-Umhüllung (ZM-U) sind der Schlüssel zu dieser Lösung.

Duktile Gussrohre im Doppelpack um die Kurve gezogen

Von Lars Kolbig und Lutz Rau

Wenn in den bereits intensiv genutzten Tiefen unter unseren Metropolen weitere Infrastrukturen gebaut werden müssen, dann werden diese Projekte immer aufwändiger, komplexer und mutieren zu wirtschaftlich-technischen Schwergewichten. Der Anteil der Materialkosten am Gesamtprojekt wird dabei zunehmend geringer, während die Anforderungen an die Betriebssicherheit über extrem lange Nutzungsdauern steigen. Duktile Gussrohre sind erste Wahl, wenn es darum geht, eine komplizierte Abwasserüberleitung im Grundwasser unter immensen Zwängen der benachbarten Strukturen zu bauen. Spannende Lektüre, selbst noch für „alte Hasen“!

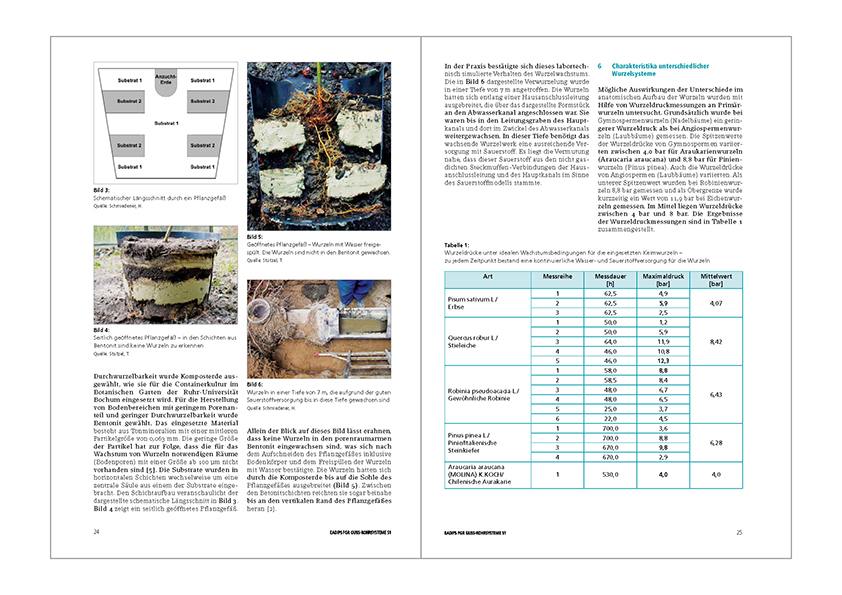

Wurzelfestigkeit von duktilen Guss-Rohrverbindungen

Von Christoph Bennerscheidt

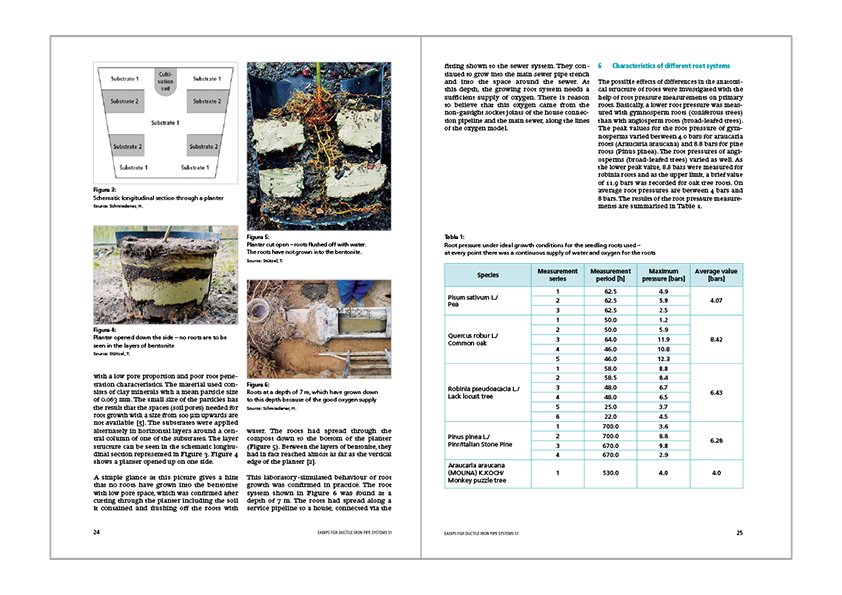

Interaktion von Baumwurzeln mit der Leitungsinfrastruktur ist seit Jahrzehnten Diskussionsstoff zwischen den Leitungsbetreibern und den Grünflächenämtern. Ein Spezialfall ist der Wurzeleinwuchs in Rohrverbindungen, der im schlimmsten Fall mit einer verstopften oder undichten Leitung endet. War früher der Hydrotropismus das gängige Ursache-Wirkungs-modell, bei dem die Wurzel dem Wasser entgegenwächst, also eine bereits geringfügige Leckage benötigt, so ist nach den Forschungsergebnissen der letzten 15 Jahre die Verfügbar-

keit von Sauerstoff bei zu geringem Anpressdruck des Dichtelements die wirkliche Ursache für den Wurzeleinwuchs. Daraus erwachsen konkrete Anforderungen an Steckmuffen-Verbindungen von Kanal- und Wasserrohren, die zunehmend in den Produktnormen ihren Niederschlag finden.

Fusion Bonded Epoxy Resicoat R4® schützt erdüberdeckte Gusskomponenten seit über 25 Jahren vor Korrosion

Von Torsten Leitermann

Die Entwicklung der Epoxidharz-Pulver-Be-schichtung von Formstücken und Armaturen aus duktilem Gusseisen ist eine Erfolgsgeschichte, vor allem deswegen, weil von Anfang an konsequent auf Einhaltung höchster Anforderungen geachtet wurde. Der Beitrag fasst den neuesten Stand der Technik zusammen. Er reicht von der Polymerisationschemie des Epoxidharzes, Pulverherstellung und -verarbeitung über den Nachweis der Korrosionsschutzwirkung durch mehrere Messmethoden bis zur Darstellung der trinkwasserhygienischen Eignung mit Blick auf nationale und europäische Regularien. Wer mehr als einen oberflächlichen Eindruck von dieser Techno-logie bekommen möchte, der findet hier Antwort auf die wichtigsten Fragen.

Landeshauptstadt von Sachsen-Anhalt setzt auf Armaturen und Formstücke aus duktilem Gusseisen mit Epoxidharz-Pulver-Beschichtung

von Sigmund Pionty und René Pehlke

Eine Großstadt mit hohen Verkehrslasten, gleichzeitigem Ausbau der Straßenbahntrassen: hier werden höchste Anforderungen an die Langlebigkeit der Leitungsinfrastruktur gestellt. Armaturen und Formstücke aus modernen Gusswerkstoffen mit integralem Korrosionsschutz geben dem Betreiber die Gewähr für eine lange Nutzungsdauer bei geringstem Instandhaltungsbudget.

Die neue Generation weichdichtender Schieber

Von Matthias Müller

Nichts ist so gut, als dass es nicht noch weiter verbessert werden kann. Diese bekannte Aussage behält ihren Wahrheitsgehalt umso mehr, je enger die Zusammenarbeit zwischen Hersteller und Anwender eines Produkts ist. Die Entwicklung neuer Fertigungstechnologien und neuer Werkstoffe wird vom Hersteller genau beobachtet, vom Anwender kommen Wünsche und Beobachtungen aus dem täglichen Betrieb. In der Entwicklungsabteilung des Herstellers laufen diese Informationen zusammen und ergeben so einen stetigen Fluss von Innovationen. Der neue Keilschieber INFINITY ist ein sprechendes Beispiel!

Neubau einer UV-Desinfektionsanlage im Wasserwerk Menden-Halingen der Wasserwerke Westfalen GmbH

Von Dietmar Hölting

Trinkwassertransport mit höchsten hygienischen Anforderungen, wie sie erst in der Zukunft zu erwarten sind, mit Rohrleitungsmaterial, welches durch stark aggressives Bettungsmaterial beansprucht wird, das ist das Spielfeld für emaillierte Formstücke und Armaturen. Dazu ein Betreiber, der sich bei seinen Lieferanten aktiv in die Optimierung seiner Komponenten einbringt, das alles ist die Voraussetzung für das hohe Qualitätsniveau unseres Trinkwassers. Innen und außen emaillierte Armaturen bieten Gewähr für extrem lange Nutzungsdauer bei trinkwasserhygienischer Höchstleistung.

Unser Antrieb für Innovation ist Optimierung

Von Ursula Ritter

Nichts ist so gut, dass es im Detail nicht noch weiter verbessert werden kann! Diese Feststellung der Autorin zeigt direkt die Gründe dafür auf, warum viele unserer mittelständischen Unternehmen in der Welt als „hidden champions“ angesehen werden. Ihre enge Verbindung mit der Gedankenwelt ihrer Kunden erzeugt Innovation zum Nutzen des Kunden sowie anerkannte Marktführerschaft. Bei den Armaturen existiert ein stetiger Strom von Verbesserungen, Optimierungen, sei es am Werkstoff, an der Beschichtung, an der Konstruktion. Anders ist der Unternehmenserfolg im globalen Wettbewerb nicht zu bekommen.

Elastomerdichtungen in Trinkwasseranwendungen

Von Rüdiger Werner und Harald Hager

Von der geplanten europäischen Vereinheitlichung nationaler Regelungen im Bereich der Gesundheit und des Verbraucherschutzes sind auch Elastomer-Dichtungen im Kontakt mit Trinkwasser betroffen. Galten früher Anforderungen an den Übergang bestimmter Stoffe aus dem Elastomer an das Trinkwasser, so sind heute Positivlisten in Gebrauch, in denen die zur Produktion von Dichtungen toxikologisch bewerteten und zugelassenen Stoffe aufgeführt sind. Dies schränkt den Hersteller von Dichtungen bei der Rezeptur ein, weil eine Dichtung zusätzlich mechanische-technologische Anforderungen erfüllen muss, damit die gewünschte Langzeitfunktion (Dichtheit) eingehalten wird. Auch hier ist wieder ein ständiger Evolutionsvorgang zu beobachten.

Gesamtumfahrung Biel –

Löschwasserleitungen aus duktilem Gusseisen in den Autobahntunneln Büttenberg und Längholz

Von Roger Saner

Löschwasserleitungssysteme in Bauwerken haben ein merkwürdiges Anforderungsprofil: Sie sollen so selten wie möglich zum Einsatz kommen, müssen aber während der gesamten Nutzungsphase des Bauwerks stets zuverlässig funktionieren. Bei Löschwassersystemen in Verkehrstunneln kommen weitere Anforderungen hinzu: Nichtbrennbarkeit der Komponenten, dauerhafter Schutz der Innen- und Außenflächen, leichte Montierbarkeit unter beengten Platzverhältnissen und einiges mehr. Löschwassersysteme aus duktilem Gusseisen in Verkehrstunneln haben eine lange Tradition, weil sie die Gesamtheit aller Anforderungen in idealer Weise erfüllen, so auch dieses Mal beim Neubau eines Schweizer Autobahntunnels, wo bekanntermaßen die höchsten Sicherheitsanforderungen herrschen.

Bergbahnen Westendorf –

schneller beschneien mit duktilen Gussrohren

Von Mario Ruggenthaler

Skitourismus als essentieller Wirtschaftsfaktor, vom Klimawandel verursachte kürzere und mildere Winter, das sind die Voraussetzungen für den steigenden Bedarf von Hochdruckleitungen in den Skigebieten. Duktile Guss-Rohrsysteme mit ihren einfach und sicher montierbaren Steckmuffen-Verbindungen, mit ihrer extremen Druckbelastbarkeit, mit ihrem kompletten Formstück- und Armaturenprogramm sehen sich bei den Planern und Betreibern von Beschneiungsanlagen in einer Favoritenrolle.

Wasserkraftwerk Lago di Tomé –

Hochdruckleitung DN 400 für eine umweltfreundliche Stromproduktion

Von Roger Saner

Im alpinen Gelände schlummern trotz ausgiebig genutzter Wasserkraftressourcen immer noch beträchtliche Potenziale. Der Beitrag schildert Projektierung und Bau eines Kleinwasserkraftwerks mit einer geodätischen Höhendifferenz von fast 1.000 m im Tessin. Es lassen sich zunehmend Anstrengungen beobachten, die zu einer möglichst unauffälligen Eingliederung der Infrastrukturen in den natürlichen Gebirgsraum führen. Triebwasserleitungen aus duktilen Guss-Rohrsystemen werden dabei in Bruchsteinmauern verborgen.

Kleinwasserkraftwerk Costeana –

duktile Gussrohre als Problemlösung bei Erdbewegungen

Von Luca Frasson

Not macht erfinderisch! Beim Bau von Kleinwasserkraftwerken im alpinen Gelände tauchen oft unvermutet Probleme auf, die der Planer lösen muss. Mit Hilfe duktiler Gussrohre und Formstücke lassen sich in Zusammenarbeit mit einem kompetenten Team oft die Schwierigkeiten überwinden. Die einzig mögliche Trasse einer geplanten Turbinenleitung verläuft in einem Rutschhang. Speziell entwickelte Kompensator-Formstücke mit je 80 cm zulässiger Dehnung entschärfen das Problem.

Kraftwerksleitung für das Kraftwerk Bristen im Kanton Uri

Von Werner Volkart

Seit Langem bewährt und immer wieder beschrieben, sind duktile Guss-Rohrsysteme beim Bau von Kraftwerksleitungen einfach nicht zu schlagen! Das schwierige und unzugängliche Gelände mit seinen felsigen Böden, die hohen technischen und sicherheitsrelevanten Randbedingungen, zusätzliche Forderungen der Umweltbehörden, dies und noch mehr lassen jede Kraftwerksleitung zu einer individuellen Aufgabe werden. Wenn dann noch Passrohre nach Aufmaß und ohne Bauverzögerung, mit speziellen Anforderungen an die Längskraftschlüssigkeit und den Korrosionsschutz an den Einbauort geliefert werden müssen, dann ist der Erfahrungsschatz aller am Bau beteiligten unabdingbar. Der Bau der Triebwasserleitung für das Kraftwerk Bristen ist ein gelungenes Beispiel dafür.